Understanding the Abb Irc5 Safety Wiring Diagram is crucial for anyone working with ABB industrial robots. This diagram is not just a set of lines and symbols; it's a vital blueprint that ensures the safe operation of complex robotic systems. Effectively navigating and implementing the Abb Irc5 Safety Wiring Diagram safeguards both personnel and equipment.

What is an Abb Irc5 Safety Wiring Diagram and How is It Used?

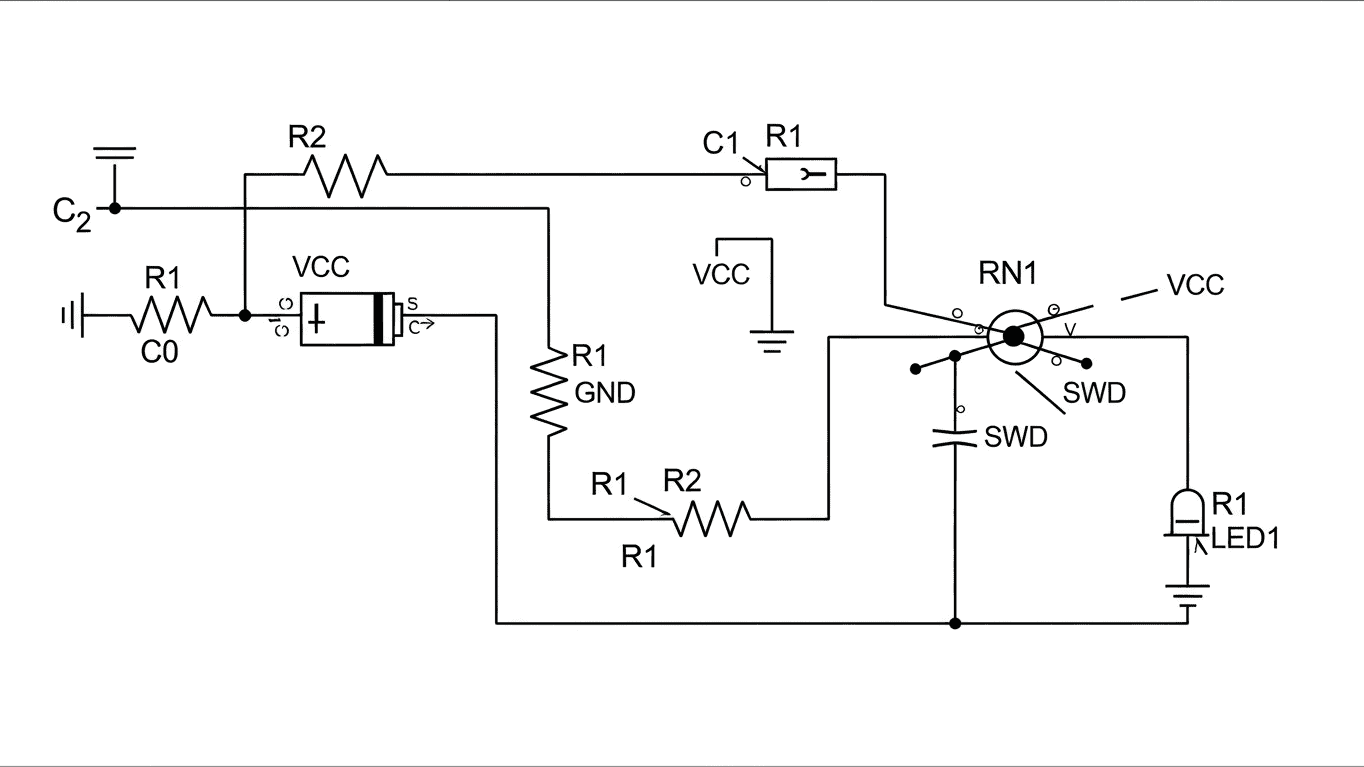

An Abb Irc5 Safety Wiring Diagram is a schematic representation that details the electrical connections for the safety circuits within an ABB IRC5 controller. These safety circuits are designed to prevent accidents and injuries by monitoring critical parameters and initiating immediate shutdowns or safe movements when predefined safety limits are breached. Think of it as the robot's guardian angel, constantly watching over its operations to maintain a secure working environment. These diagrams are indispensable for installation, troubleshooting, and maintenance.

The primary purpose of the Abb Irc5 Safety Wiring Diagram is to ensure that all safety-related functions are correctly implemented and integrated. This includes connections for emergency stop buttons, safety gates, light curtains, safety mats, and other safety devices. The diagram will specify the type of wiring required, the function of each component, and how they interact with the IRC5 controller's safety functions. The correct interpretation and application of this diagram are paramount for achieving a safe robotic cell. Here are some common elements found:

- Emergency Stop (E-Stop) circuits

- Safety Gate monitoring

- Light Curtain integration

- Two-hand control setups

- Speed monitoring

The usage of the Abb Irc5 Safety Wiring Diagram extends across various stages of a robot's lifecycle. During initial setup, it guides technicians in connecting all safety components to the controller, ensuring that safety functions are active from the very first power-up. For troubleshooting, it helps pinpoint the source of a safety fault by allowing technicians to trace the electrical path and identify any breaks or malfunctions in the safety circuit. In terms of maintenance, it provides a reference for any upgrades, modifications, or replacements of safety-related hardware. This comprehensive approach ensures that the robot's safety integrity remains high throughout its operational life. A typical safety wiring schematic might look something like this, illustrating the flow of signals:

| Component | Connection Point | Function |

|---|---|---|

| E-Stop Button | DI (Digital Input) | Initiates immediate stop upon activation |

| Safety Gate Switch | DI (Digital Input) | Monitors gate status; prevents operation when open |

| Light Curtain | Safety I/O Module | Detects presence in a hazardous area; triggers stop |

For detailed, specific guidance tailored to your exact robot model and safety configuration, always refer to the official documentation provided with your ABB IRC5 system. The information presented here is a general overview to help you understand the importance and function of the Abb Irc5 Safety Wiring Diagram.