Understanding an Ac Alternator Wiring Diagram is crucial for anyone working with electrical systems that rely on alternators, whether in vehicles, generators, or industrial machinery. A properly deciphered Ac Alternator Wiring Diagram provides a clear roadmap to connect and troubleshoot these essential components, ensuring efficient power generation and system functionality.

Decoding the Ac Alternator Wiring Diagram

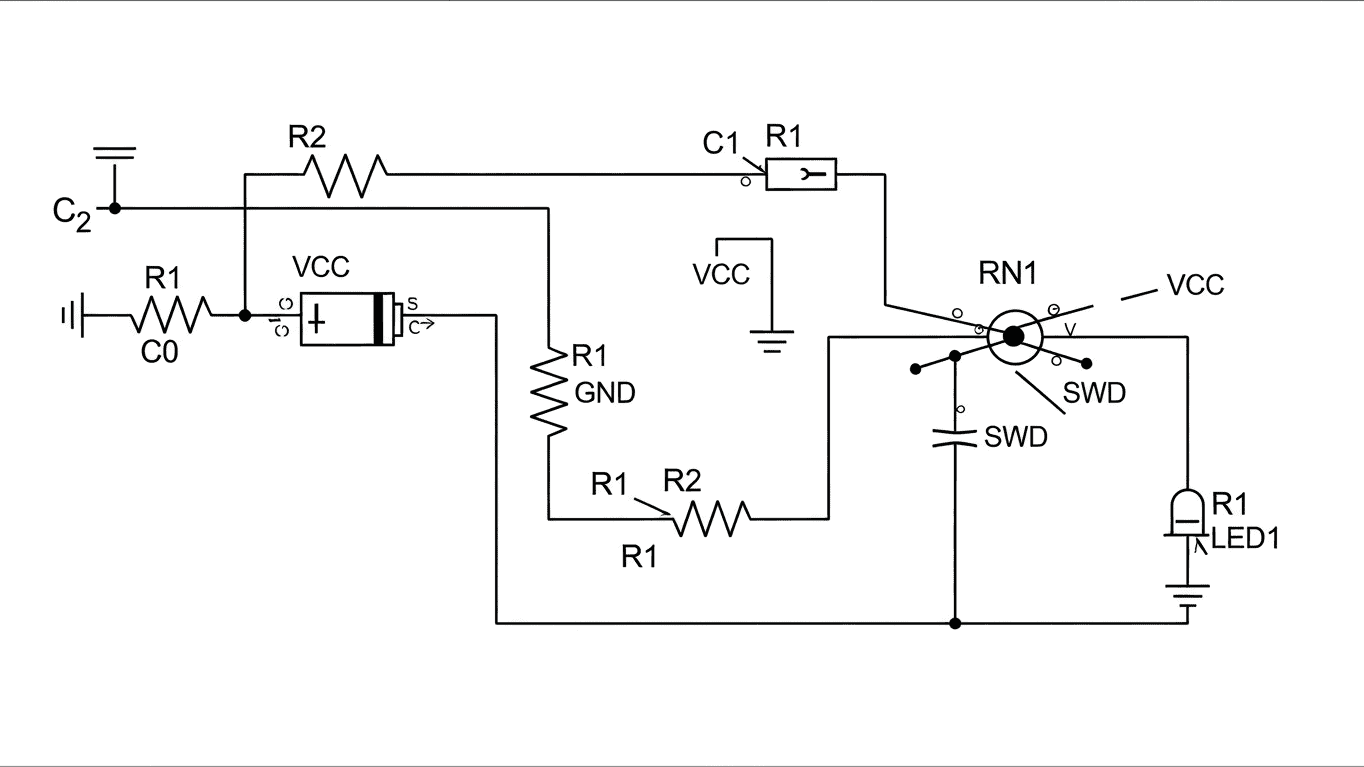

An Ac Alternator Wiring Diagram is a schematic representation that illustrates how the various wires and components of an alternator are connected. It acts as a visual guide, detailing the paths of electrical current and the function of each terminal. For instance, you'll typically find labels for the stator windings, the rotor, the rectifier, and the voltage regulator. Each of these components plays a vital role in converting mechanical energy into usable alternating current (AC) electricity. The diagram helps technicians and enthusiasts identify which wire goes where, preventing incorrect installations that could lead to damage or system failure.

The use of an Ac Alternator Wiring Diagram extends beyond simple installation. It is an indispensable tool for troubleshooting. When an alternator isn't performing as expected – perhaps not charging a battery or producing inconsistent voltage – the wiring diagram becomes the first point of reference. By following the depicted connections, one can systematically check for breaks in wires, faulty connections, or issues with specific components. The diagram often includes symbols that represent different electrical components and their operational characteristics, making it easier to diagnose problems. Key elements typically found in such diagrams include:

- Stator Winding Connections

- Rotor Field Coil Terminals

- Rectifier Output (B+)

- Ground Connections

- Voltage Regulator Input/Output

The ability to accurately read and interpret an Ac Alternator Wiring Diagram is paramount for ensuring the safety and reliability of any electrical system powered by an alternator. Without it, diagnosing issues can be a frustrating and time-consuming process, often leading to guesswork and potential further damage. The diagram provides the necessary technical information to:

- Confirm correct wiring before powering up.

- Identify specific wires for testing voltage and continuity.

- Trace the flow of current from generation to output.

- Understand how the voltage regulator interacts with the alternator.

Here's a simplified look at common terminal functions:

| Terminal | Description |

|---|---|

| B+ (or BAT) | Main output terminal for battery charging. |

| F (or FLD) | Field winding connection. |

| G (or GRD) | Ground connection. |

| L (or LAMP) | Indicator lamp connection (if applicable). |

To gain a comprehensive understanding and practical knowledge of your specific AC alternator system, it is highly recommended to consult the detailed diagrams available in your equipment's service manual.