The Ac Compressor Start Relay Wiring Diagram is a fundamental blueprint for anyone looking to understand how their air conditioning system's compressor is powered up. This diagram illustrates the intricate electrical pathways that allow the compressor, the heart of your AC, to receive the initial surge of power it needs to begin cooling your home. Understanding this Ac Compressor Start Relay Wiring Diagram is key to troubleshooting and maintaining your system's efficiency.

The Role of the Ac Compressor Start Relay Wiring Diagram

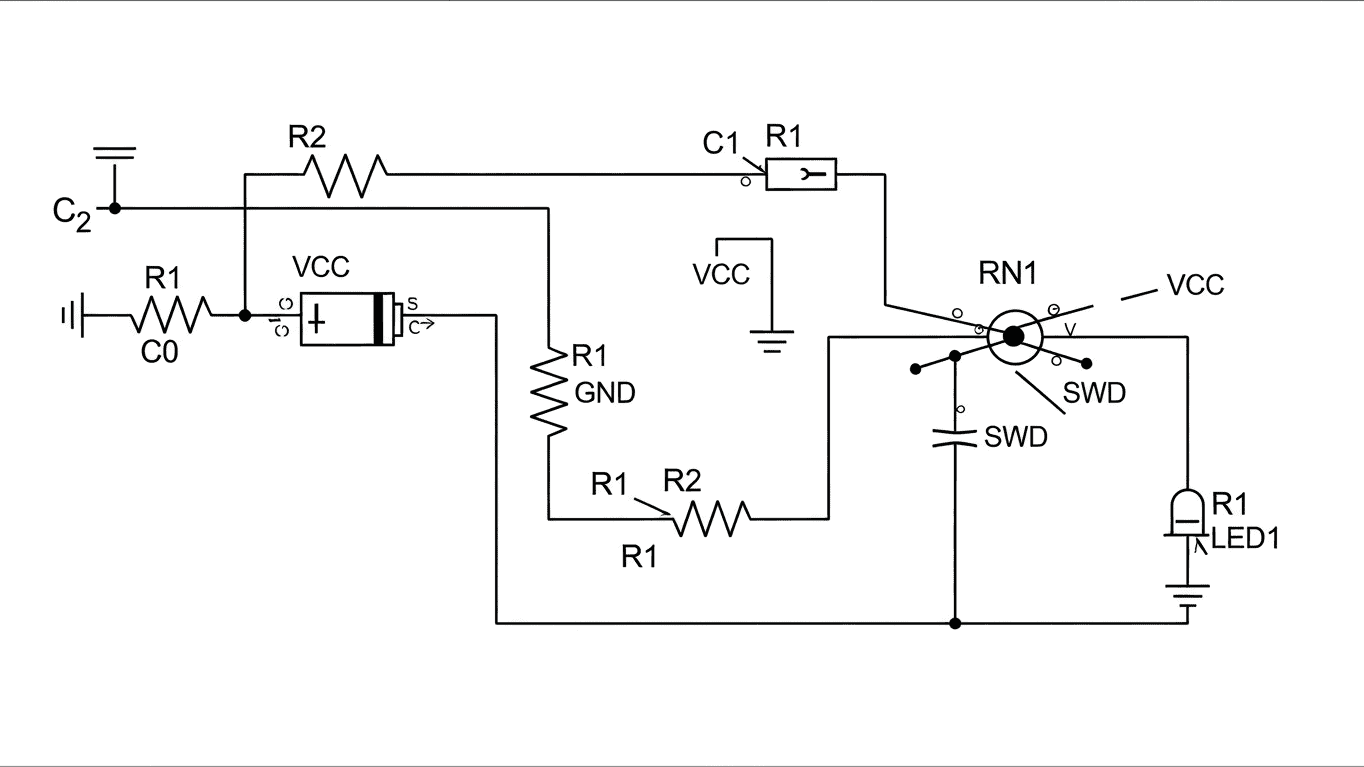

At its core, an Ac Compressor Start Relay Wiring Diagram shows the relationship between the start relay, the compressor, and other electrical components like capacitors and the thermostat. The start relay's primary function is to provide an extra jolt of power to the compressor motor during its initial startup phase. This is essential because AC compressors require more power to overcome inertia and begin rotating compared to the power needed to keep them running smoothly. Without the start relay, the compressor might struggle to start, overheat, or not start at all.

The Ac Compressor Start Relay Wiring Diagram typically involves a few key connections. The relay itself is usually a small, cylindrical device connected to the compressor's electrical terminals. When the thermostat calls for cooling, it sends a signal that energizes the start relay. This action closes a set of contacts within the relay, completing a circuit that bypasses the main run winding of the compressor motor and instead directs power to the start winding. This provides the necessary torque. Once the compressor reaches a certain speed, a centrifugal switch within the relay (or a current-sensing mechanism in some designs) disengages the start winding, and the compressor then runs on its main winding. This process is crucial for:

- Ensuring reliable compressor startup.

- Preventing motor damage from insufficient starting torque.

- Optimizing energy consumption by only engaging the start circuit when needed.

Different types of AC systems will have variations in their Ac Compressor Start Relay Wiring Diagram. For instance, some systems might use a capacitor-start, capacitor-run motor, which involves both a start capacitor and a run capacitor, both integrated into the relay circuit. The wiring diagram will meticulously map out how these components interact. Here’s a simplified look at common components you'd find in a diagram:

| Component | Function |

|---|---|

| Start Relay | Provides initial high-torque power to the compressor. |

| Start Capacitor | Increases starting torque. |

| Run Capacitor | Improves running efficiency and power factor. |

| Compressor Motor Windings | Main winding for running, start winding for initial push. |

Understanding these relationships, as depicted in the Ac Compressor Start Relay Wiring Diagram, is vital for anyone performing diagnostics or repairs. It allows technicians to trace power flow, identify faulty components, and correctly reassemble the electrical connections.

To gain a deeper understanding and to access specific schematics relevant to your AC unit, please refer to the detailed diagrams and component explanations found in the service manual for your specific air conditioning model.