Understanding the "Ac Motor Start Capacitor Wiring Diagram" is crucial for anyone working with single-phase AC motors, especially those involved in maintenance, repair, or even simple DIY projects. This diagram is your roadmap to correctly connecting the starting capacitor, a vital component that helps initiate the rotation of the motor's rotor. Without a proper understanding of the Ac Motor Start Capacitor Wiring Diagram, you risk damaging the motor or experiencing poor performance.

Understanding the Role of the Start Capacitor

The start capacitor, often a cylindrical component with two terminals, plays a pivotal role in getting an AC motor spinning. Single-phase AC motors, by themselves, lack the inherent starting torque needed to overcome the inertia of their own rotor and the load they're intended to drive. This is where the start capacitor comes in. It's wired in series with a starting winding (also known as the auxiliary winding) and is connected to the main winding. When power is applied, the capacitor creates a phase shift in the current flowing through the starting winding, generating a rotating magnetic field that provides the initial push to start the motor. The correct wiring of the start capacitor is therefore of paramount importance for motor functionality and longevity.

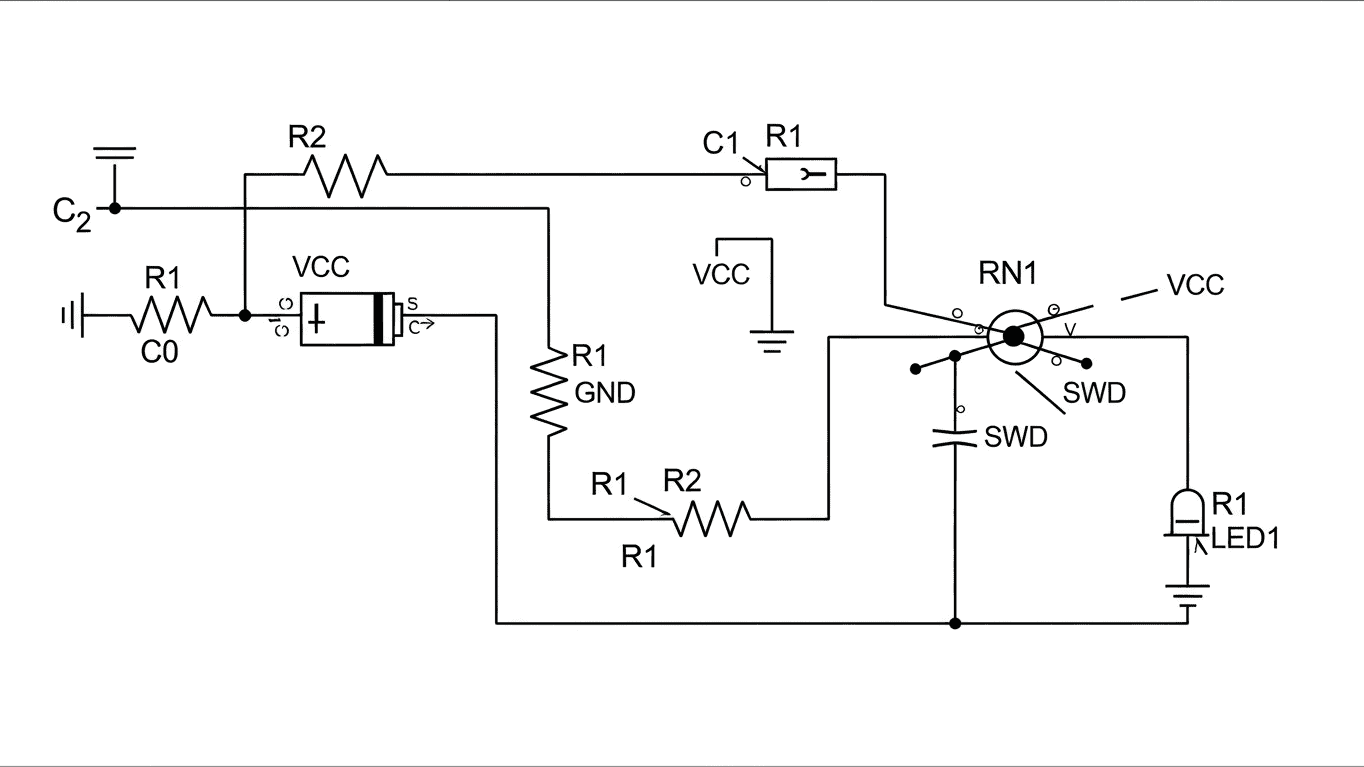

The "Ac Motor Start Capacitor Wiring Diagram" illustrates how this starting mechanism operates. Typically, the starting winding and its associated capacitor are only active during the startup phase. Once the motor reaches a certain speed (usually around 75% of its rated speed), a centrifugal switch or a potential relay disengages the starting winding and the capacitor, allowing the motor to run solely on its main winding. This ensures efficient operation and prevents the capacitor from overheating and failing. The diagram will show:

- The main winding of the motor.

- The starting (auxiliary) winding.

- The start capacitor.

- The centrifugal switch or potential relay.

- Connections to the power supply (line and neutral).

Different types of AC motors will have slightly varied wiring configurations, but the fundamental principle remains the same. For instance, a direct-on-line (DOL) starter might have a simpler setup compared to a motor controlled by a more complex control circuit. Always refer to the specific "Ac Motor Start Capacitor Wiring Diagram" for your particular motor model. Consulting a reliable diagram ensures you connect the capacitor and other components in the correct sequence and polarity (if applicable). A table summarizing common connections might look like this:

| Component | Connection Point |

|---|---|

| Start Capacitor | In series with the starting winding, and in parallel with the main winding during startup. |

| Centrifugal Switch | In series with the starting winding and capacitor, to disconnect them at speed. |

| Starting Winding | Connected to one end of the main winding and to the power supply via the start capacitor and centrifugal switch. |

To ensure you are connecting your AC motor's start capacitor correctly, refer to the specific wiring diagram provided by the manufacturer for your motor. You can often find these diagrams within the motor's user manual or on the motor's nameplate.