Understanding the Accu-coder Encoder Wiring Diagram is crucial for anyone working with industrial automation, motion control systems, or precise measurement applications. This diagram serves as a roadmap, guiding you through the correct connections to ensure your Accu-coder encoder functions reliably and accurately within your system. A properly interpreted Accu-coder Encoder Wiring Diagram is the first step to successful integration and operation.

What is an Accu-coder Encoder Wiring Diagram and How is it Used?

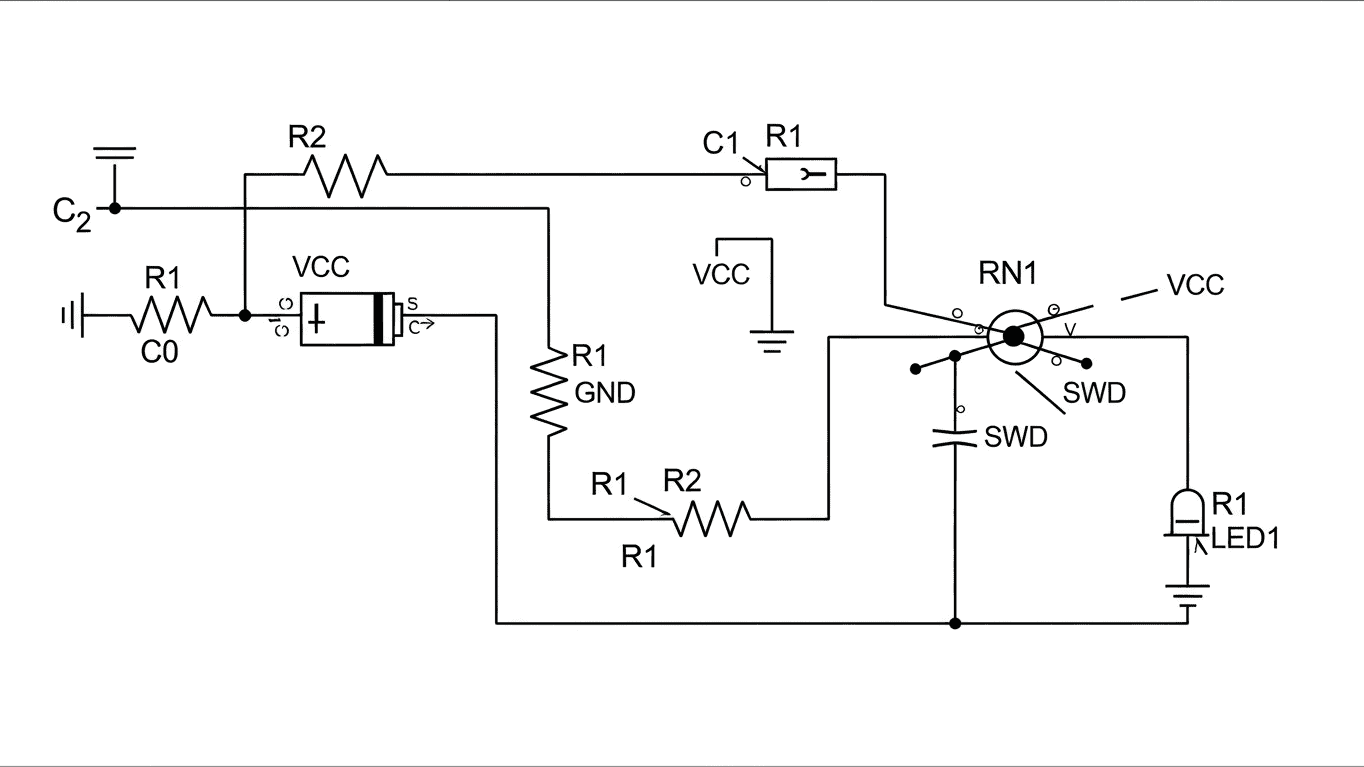

An Accu-coder Encoder Wiring Diagram is a schematic that illustrates the electrical connections between an Accu-coder encoder and the control system or device it's interfacing with. It details each pin on the encoder and its corresponding connection point on the receiving end, whether that's a programmable logic controller (PLC), a motor drive, or a dedicated counter. These diagrams are indispensable because they prevent incorrect wiring, which can lead to data loss, system malfunctions, or even permanent damage to the encoder or other components. The importance of adhering strictly to the Accu-coder Encoder Wiring Diagram cannot be overstated for system integrity and performance.

Encoders, in general, translate mechanical motion into electrical signals. Accu-coder specializes in producing high-quality encoders for various applications. The wiring diagram is specific to the model and type of encoder you are using. For example, a simple incremental encoder will have a different wiring configuration than a more complex absolute encoder. These diagrams often detail:

- Power supply connections (Vcc and Ground).

- Signal outputs (A, B, and Z channels for incremental encoders, or serial data lines for absolute encoders).

- Optional connections for index pulses or alarm signals.

- Shielding and grounding recommendations for noise reduction.

Using the Accu-coder Encoder Wiring Diagram involves carefully identifying each wire from the encoder and matching it to the correct terminal or pin on your control system. This process typically involves:

- Locating the specific wiring diagram for your Accu-coder encoder model.

- Identifying the function of each wire and connector on the diagram.

- Verifying the voltage and current requirements of the encoder and ensuring your power supply meets these specifications.

- Making the physical connections, ensuring proper insulation and strain relief.

Here's a simplified representation of common connections found in many encoder wiring diagrams:

| Encoder Pin/Wire | Function | Typical Connection Point |

|---|---|---|

| Vcc | Positive Power Supply | +24VDC or similar |

| GND | Ground | 0VDC or Ground terminal |

| A | Channel A Output | Input of PLC counter or encoder interface |

| B | Channel B Output | Input of PLC counter or encoder interface |

| Z (Index) | Index Pulse Output | Dedicated Index input on PLC or interface |

To ensure your Accu-coder encoder is connected correctly and operates at its full potential, always refer to the specific Accu-coder Encoder Wiring Diagram provided with your unit. This detailed guide is your most reliable resource for accurate and safe installation.