Understanding the Air Compressor Electrical Wiring Diagram is crucial for anyone working with air compressors, whether for maintenance, repair, or even initial setup. This diagram acts as the blueprint for how electricity flows through your compressor, powering its motor and controls. It's the key to troubleshooting issues and ensuring safe operation.

The Blueprint of Power: Understanding Your Air Compressor Electrical Wiring Diagram

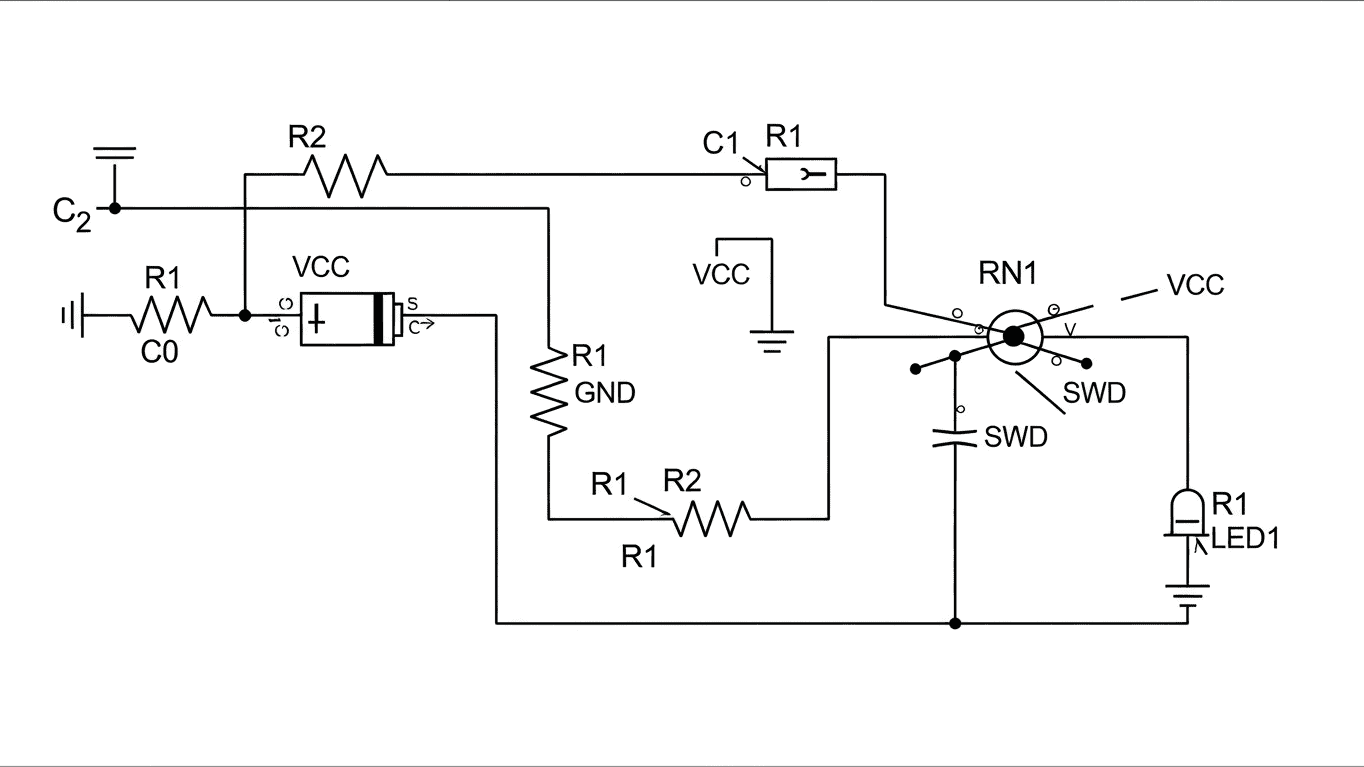

An Air Compressor Electrical Wiring Diagram is essentially a schematic that illustrates the electrical components of an air compressor and how they are connected. It uses standardized symbols to represent various parts like motors, switches, relays, capacitors, and power sources. By following the lines and symbols, you can trace the path of electricity from the power outlet to the compressor's motor and back. This visual representation is invaluable for diagnosing problems, as it allows you to pinpoint potential breaks in the circuit or malfunctioning components. The importance of a correctly interpreted wiring diagram cannot be overstated for safe and effective compressor operation.

These diagrams are used in several critical ways. For technicians, they are the primary tool for troubleshooting electrical faults. If a compressor isn't starting or is running erratically, the diagram helps them systematically check each connection and component. For DIY enthusiasts, it can guide them through the process of replacing a faulty switch or motor. Furthermore, when installing a new compressor or modifying an existing setup, the diagram ensures that all connections are made according to manufacturer specifications and electrical codes. A typical diagram might show:

- Power input connections

- Motor winding configurations

- Switch and relay placements

- Capacitor connections

- Safety features like overload protection

The complexity of an Air Compressor Electrical Wiring Diagram can vary significantly depending on the type and size of the compressor. A small, portable compressor might have a very simple diagram, while a large industrial unit could have a much more intricate one. Regardless of complexity, they all serve the same fundamental purpose: to provide a clear and accurate guide to the electrical system. Understanding these diagrams can also empower you to make informed decisions about repairs and maintenance, potentially saving you time and money. It is helpful to have a table to quickly reference common symbols, such as:

| Symbol | Component |

|---|---|

| Line | Power Source |

| Circle with an 'M' | Motor |

| Dashed Line | Control Circuit |

To get the most accurate and specific information for your air compressor, always refer to the manufacturer's provided Air Compressor Electrical Wiring Diagram. It's the definitive guide for your particular model and will ensure all work is done correctly and safely.