Understanding an Air Ride Wiring Diagram is crucial for anyone looking to install, troubleshoot, or simply gain a deeper appreciation for their vehicle's air suspension system. This diagram serves as the roadmap for how electricity flows through your air ride components, ensuring everything from your compressors to your valves operates in harmony. A properly understood Air Ride Wiring Diagram is the key to a reliable and comfortable ride.

What is an Air Ride Wiring Diagram and How is it Used?

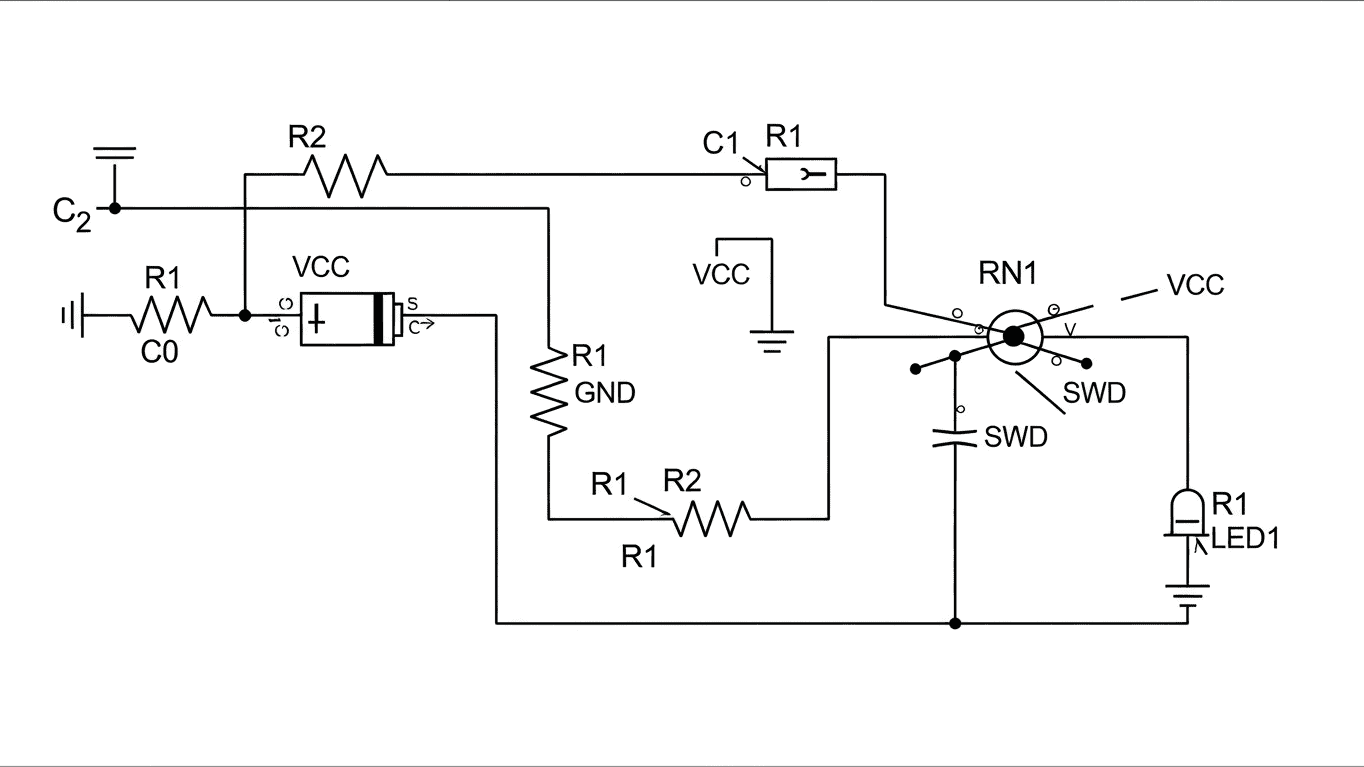

At its core, an Air Ride Wiring Diagram is a schematic that illustrates the electrical connections between all the components of an air suspension system. It shows how power is supplied, how signals are transmitted, and how various parts interact. Think of it as the blueprint for your air ride's electrical nervous system. Without this diagram, diagnosing electrical issues or making modifications would be like navigating a complex maze blindfolded. The importance of having a clear and accurate Air Ride Wiring Diagram cannot be overstated. It ensures safety, functionality, and longevity of your air suspension.

These diagrams are indispensable tools for a variety of tasks. For installers, they provide a step-by-step guide to connect each wire to its correct terminal. For technicians, they are the primary resource for pinpointing faults. For enthusiasts, they offer insights into the system's design and potential upgrades. Key elements typically found on an Air Ride Wiring Diagram include:

- Compressor power and control wires

- Solenoid valve connections

- Pressure sensor wiring

- Switch or control unit interfaces

- Ground points

Here's a simplified look at how components might be interconnected, as often depicted in a diagram:

| Component | Electrical Connection |

|---|---|

| Power Source (Battery) | Relay, Fuse |

| Relay | Switches, Compressor |

| Control Unit | Switches, Solenoid Valves, Sensors |

| Solenoid Valves | Control Unit, Air Lines |

The sequence of connections is vital. For example, a common setup involves a pressure switch that activates the compressor only when needed, conserving power and reducing wear. The control unit then dictates which solenoid valves open or close to raise or lower specific corners of the vehicle based on user input from switches or a handheld controller. Each wire, color-coded and labeled, has a specific purpose and must be connected precisely as shown.

To get the most out of your air ride system, consult the specific Air Ride Wiring Diagram provided by your system's manufacturer. This will give you the most accurate and detailed information for your particular setup.