Understanding the Allen Bradley Stack Light Wiring Diagram is crucial for anyone working with industrial automation and control systems. This diagram provides a clear roadmap for correctly connecting and powering these vital visual signaling devices. Whether you are installing a new system or troubleshooting an existing one, a proper grasp of the Allen Bradley Stack Light Wiring Diagram ensures efficient and safe operation.

What is an Allen Bradley Stack Light Wiring Diagram and How is it Used?

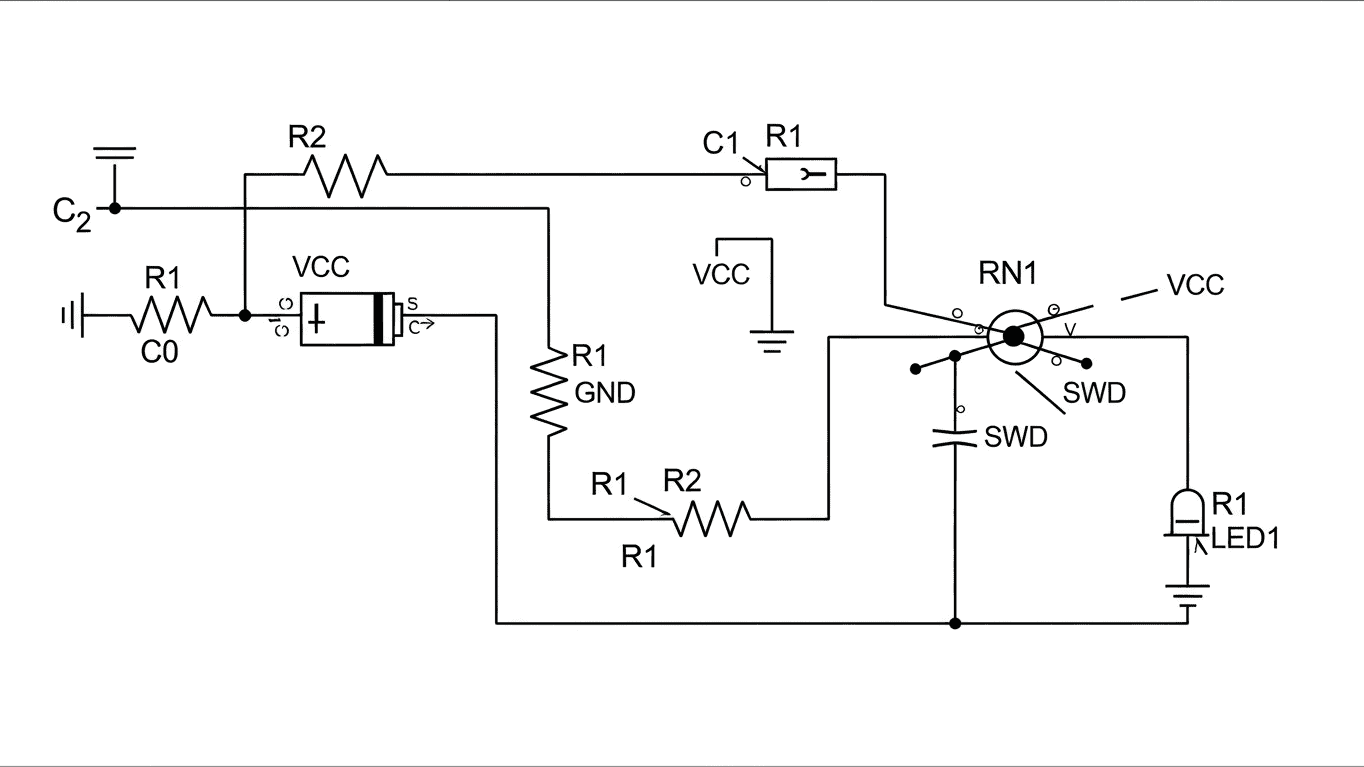

An Allen Bradley Stack Light Wiring Diagram is a schematic that illustrates the electrical connections for a stack light manufactured by Allen Bradley. Stack lights, also known as tower lights or signal towers, are multi-colored lights stacked vertically on a single unit, used to visually indicate the status of machinery or a process. They typically feature different colors like red, yellow, and green, each signifying a specific operational state, such as alarm, warning, or normal operation. The wiring diagram shows how to connect the power source, control signals, and individual light modules within the stack light assembly.

The primary purpose of the Allen Bradley Stack Light Wiring Diagram is to ensure that each light module receives the correct voltage and is activated by the intended control signal. Without it, connecting the wires haphazardly could lead to several issues:

- Damage to the stack light components.

- Incorrect signaling, potentially leading to operational errors.

- Electrical hazards and safety risks.

The importance of consulting the Allen Bradley Stack Light Wiring Diagram cannot be overstated for reliable and safe system integration.

These diagrams are essential for various tasks:

- Installation: Technicians use the diagram to make the initial connections between the PLC (Programmable Logic Controller) outputs, power supply, and the stack light.

- Troubleshooting: When a light isn't functioning as expected, the wiring diagram helps diagnose the problem, whether it's a loose connection, a blown fuse, or a faulty signal.

- Modification: If the signaling requirements change, the diagram guides engineers in reconfiguring the connections.

A typical wiring diagram might show connections like this:

| Stack Light Module | Wire Color (Example) | Connection Point |

|---|---|---|

| Red (Alarm) | Red | PLC Output 1 |

| Yellow (Warning) | Yellow | PLC Output 2 |

| Green (Running) | Green | PLC Output 3 |

| Common (Power) | Black | Power Supply Negative |

Refer to the specific Allen Bradley Stack Light Wiring Diagram that came with your unit for accurate and detailed information. This will ensure you have the correct schematic for your model and application.