An Alternator Welder Wiring Diagram is a crucial blueprint for anyone working with or building their own welding equipment. It visually represents how the various electrical components of an alternator-based welding machine are connected, ensuring proper functionality and safety. Understanding this diagram is fundamental to setting up, troubleshooting, and maintaining your welding setup.

What is an Alternator Welder Wiring Diagram and How is it Used?

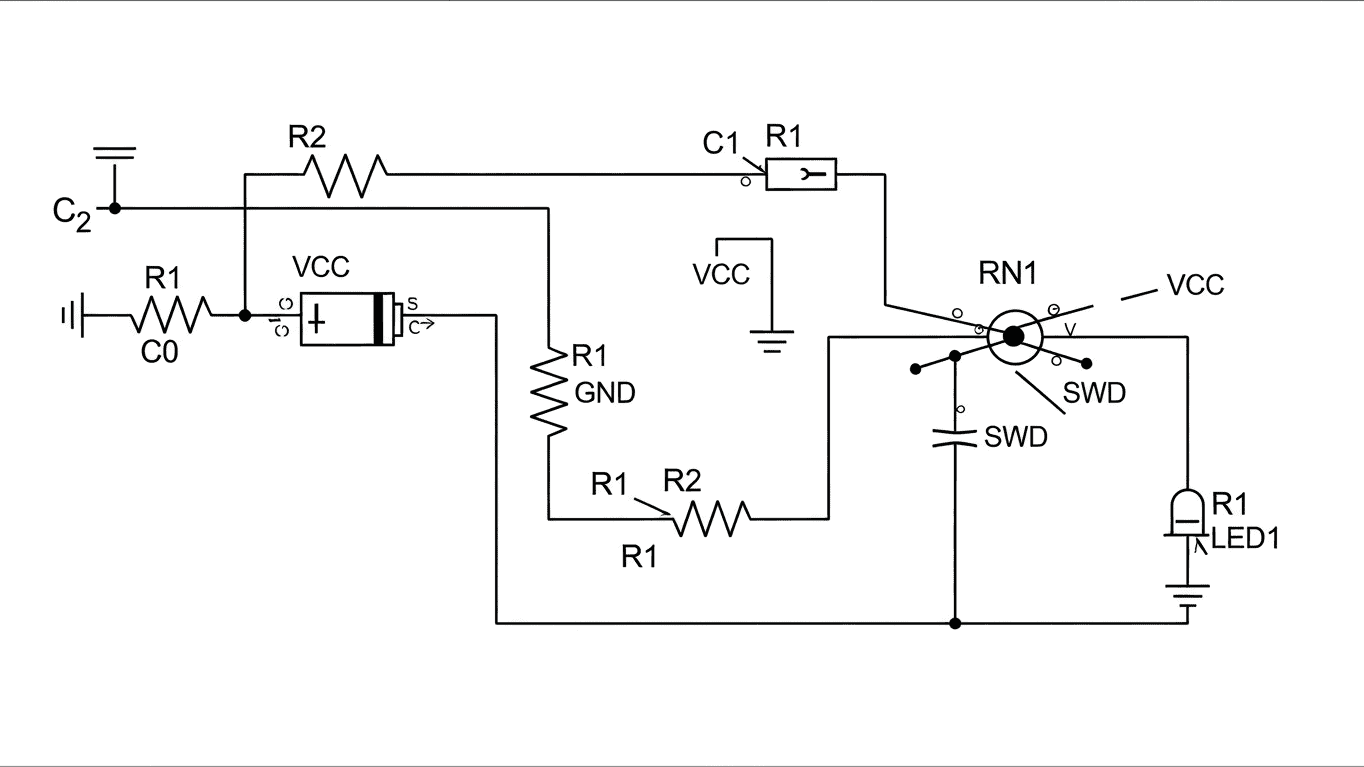

An Alternator Welder Wiring Diagram is essentially a schematic that shows the electrical connections between the alternator (which generates the welding current), the engine or motor driving it, the voltage regulator, and the welding output terminals. It details the flow of electricity, identifying key components like the field windings, stator, rectifier, and any associated control circuitry. Without this diagram, assembling or repairing an alternator welder would be a complex and potentially dangerous task. The importance of correctly following an Alternator Welder Wiring Diagram cannot be overstated, as it directly impacts the quality of your welds, the longevity of your equipment, and your personal safety.

These diagrams serve multiple purposes. For DIY enthusiasts building a welder from an alternator, the diagram provides the step-by-step guide needed for a successful build. For those troubleshooting an existing machine, it helps pinpoint faulty connections or components. Technicians use it to understand the machine's internal workings and diagnose issues efficiently. Here are some common uses:

- Component identification

- Connection verification

- Troubleshooting electrical faults

- Modification planning

The specific layout of an Alternator Welder Wiring Diagram can vary depending on the type of alternator used (e.g., automotive, industrial), the voltage regulator system, and any added features. However, the core principles remain consistent. A typical diagram will show:

- The power source (engine/motor) driving the alternator shaft.

- The internal components of the alternator (rotor, stator, rectifier).

- The output from the alternator, which is then conditioned.

- The voltage regulator's connection to control the alternator's output.

- The final welding output terminals, often with polarity markings.

Understanding the symbols and conventions used in the diagram is key. For example, different lines might represent AC or DC current, and specific symbols denote resistors, capacitors, diodes, and other electrical parts. A basic table of common symbols might look like this:

| Symbol | Component |

|---|---|

| ~ | Alternating Current (AC) |

|

◊ |

Diode |

| ◉ | Resistor |

When working with your Alternator Welder Wiring Diagram, ensure you have a clear, high-resolution copy. Always disconnect power before making any connections or adjustments. If you are unsure about any part of the wiring, it is always best to consult with an experienced individual or a professional. Taking the time to understand the diagram thoroughly will save you time, frustration, and potentially costly mistakes.

For detailed and specific information relevant to your particular alternator welder project, please refer to the dedicated resources provided alongside your equipment or build plans. These sources are designed to offer the precise guidance you need.