Understanding the Arb Twin Compressor Wiring Diagram is crucial for anyone looking to properly install and operate this powerful air compressor system. This diagram serves as a roadmap, guiding you through the intricate connections needed to ensure your compressor functions safely and efficiently. Whether you're a seasoned off-roader or a DIY enthusiast, a clear grasp of the Arb Twin Compressor Wiring Diagram will save you time, prevent potential headaches, and ultimately, maximize the performance of your equipment.

The Essentials of an Arb Twin Compressor Wiring Diagram

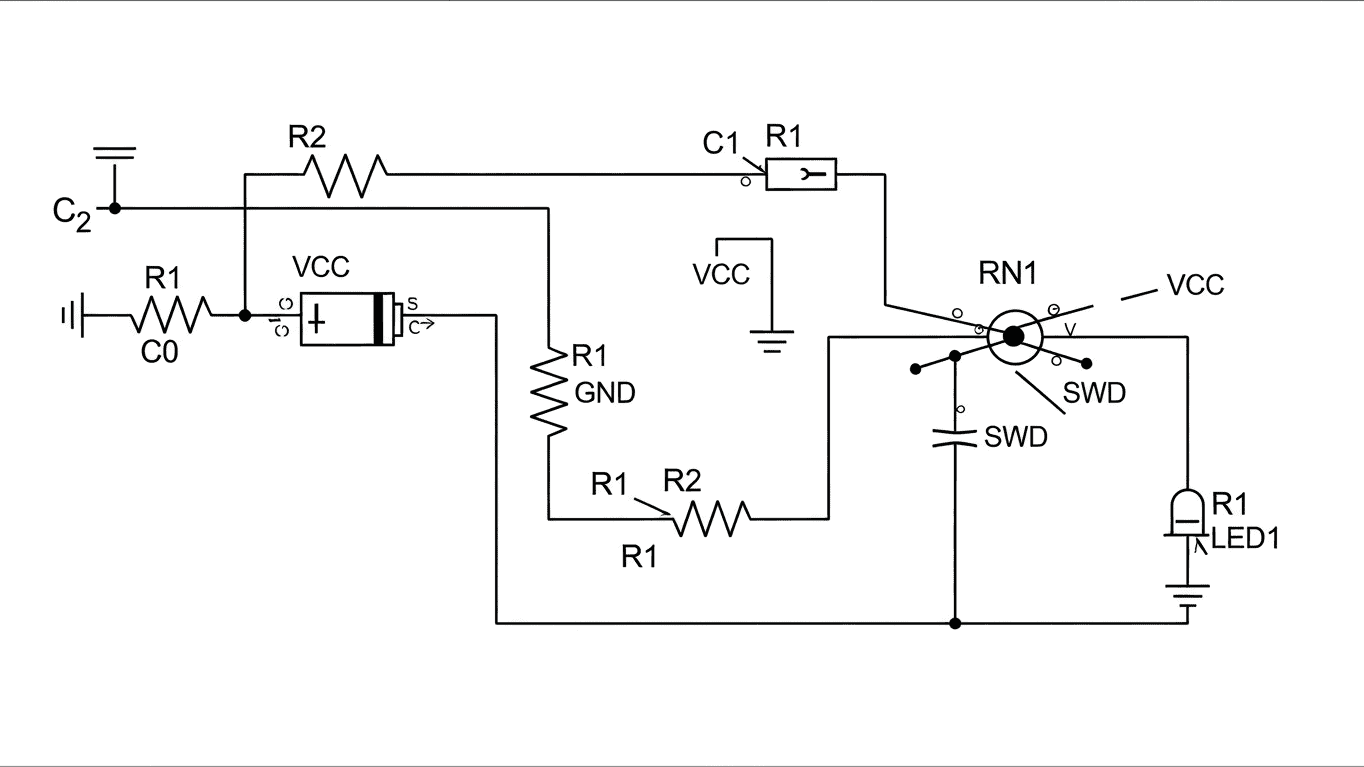

The Arb Twin Compressor Wiring Diagram is essentially a visual blueprint that illustrates how all the electrical components of your twin compressor system are interconnected. It details the flow of power from your vehicle's battery to the compressor motors, including all the safety devices and controls in between. This diagram is indispensable because it outlines the correct gauge of wire to use, the proper placement of fuses and relays, and the specific terminals each wire should connect to. Without the correct wiring, your compressor may not function, could be damaged, or even pose a fire hazard.

These diagrams are typically provided by ARB with their compressor kits. They are designed to be clear and concise, using standard electrical symbols that most people with a basic understanding of automotive wiring can interpret. The complexity arises from managing the power demands of two motors simultaneously, which necessitates robust wiring and protection. A typical diagram will include:

- Battery positive (+) and negative (-) connections

- Wire gauge recommendations

- Fuse ratings and locations

- Relay specifications and pinouts

- Switches and controller connections

- Grounding points

The purpose of meticulously following the Arb Twin Compressor Wiring Diagram is to ensure a safe and reliable electrical circuit. For instance, the diagram will specify the use of inline fuses to protect the compressor motors from overcurrent situations. It also details the correct gauge of wire to handle the high amperage draw, preventing the wires from overheating. You'll also find instructions on how to properly connect the switches that activate the compressor, ensuring they are rated for the load. Understanding these elements is not just about making the compressor work; it's about making it work correctly and safely for years to come. Here's a breakdown of common components you'll see:

| Component | Function |

|---|---|

| Relay | Acts as an electrically operated switch, allowing a low-current signal to control a high-current circuit. |

| Fuse | A safety device that melts and breaks the circuit if the current exceeds a safe level. |

| Switch | Allows the user to manually turn the compressor on and off. |

When referencing the Arb Twin Compressor Wiring Diagram, always ensure you are using the diagram specific to your model of compressor and vehicle. Minor variations can exist. It's also vital to confirm that your vehicle's electrical system can handle the additional load of the compressor. A qualified auto electrician can assist with this assessment and the installation process if you are unsure.

For a complete and detailed understanding of how to wire your ARB Twin Compressor, please refer to the official installation manual and the specific wiring diagram provided with your ARB Twin Compressor kit. This will ensure all connections are made accurately and safely, allowing you to enjoy the benefits of your powerful air compressor.