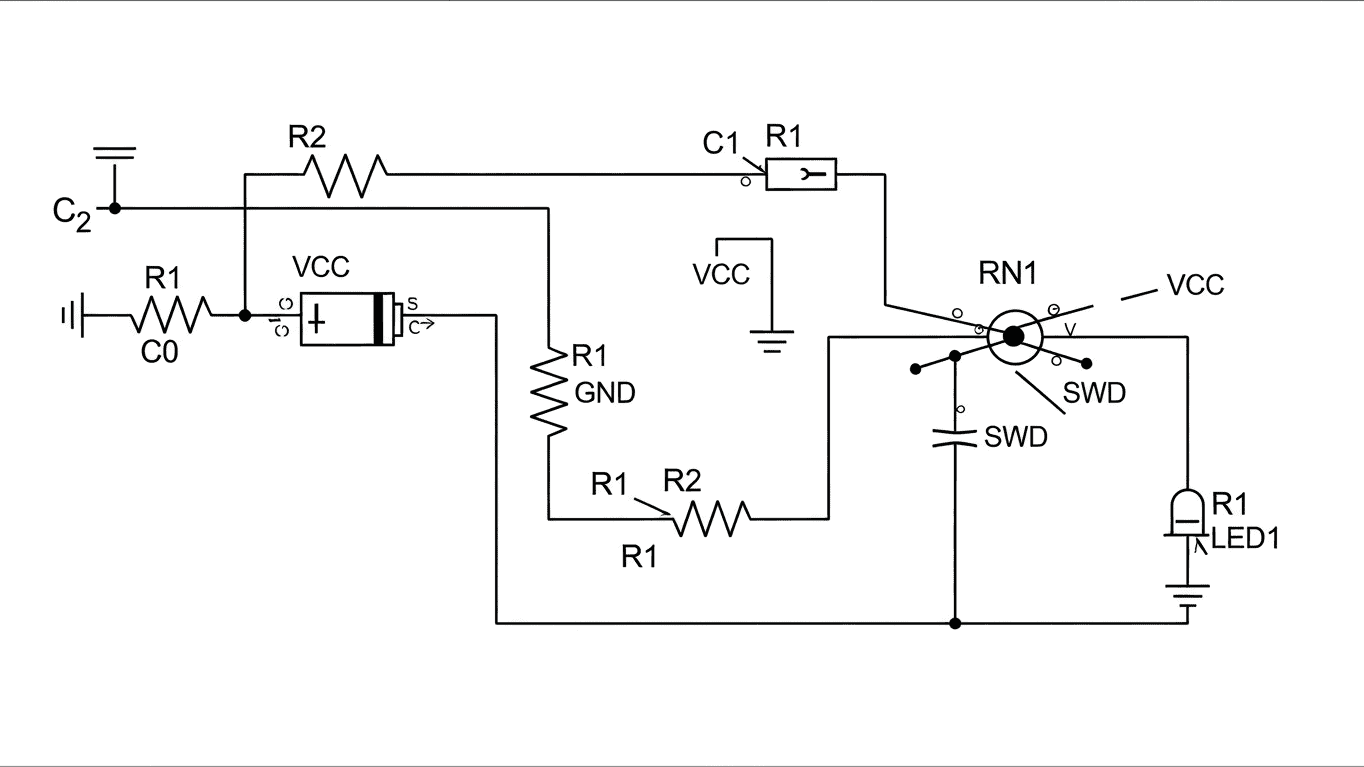

Understanding an Auxiliary Contactor Wiring Diagram is crucial for anyone working with electrical control systems. This diagram serves as a blueprint, illustrating how auxiliary contacts are integrated into a larger circuit, enabling more complex control functions and providing vital feedback. A properly understood Auxiliary Contactor Wiring Diagram ensures safe and efficient operation of machinery.

The Role and Application of Auxiliary Contacts

Auxiliary contacts are essentially small switches that are mechanically linked to the main contacts of a power contactor. When the power contactor energizes and its main contacts close to conduct current to a load, the auxiliary contacts also change their state. These contacts are typically used for control and signaling purposes, not for carrying the main load current. They are invaluable for creating interlocks, sequence operations, and monitoring the status of the main contactor. The reliable functioning of these auxiliary contacts is paramount for the overall safety and operational integrity of the system.

Here are some common applications where an Auxiliary Contactor Wiring Diagram is essential:

- Self-Holding Circuits: Allowing a control signal to remain active even after the initial trigger is removed.

- Interlocking: Preventing two motors from starting simultaneously or ensuring one device is off before another starts.

- Indicator Lights: Signaling whether a motor is running or if a contactor is energized.

- Alarm Systems: Triggering an alarm if a contactor fails to operate correctly.

The wiring of these auxiliary contacts can be simplified by understanding their different types and how they connect. The two primary types are:

| Type | Function |

|---|---|

| Normally Open (NO) | Opens when the contactor is de-energized and closes when the contactor is energized. |

| Normally Closed (NC) | Closes when the contactor is de-energized and opens when the contactor is energized. |

A typical Auxiliary Contactor Wiring Diagram will show how these NO and NC contacts are wired into a control circuit. For example, an NC auxiliary contact from Contactor A might be wired in series with the coil of Contactor B. This creates an interlocking function, ensuring that if Contactor A is energized, Contactor B cannot be energized. Conversely, an NO auxiliary contact from Contactor A could be used to energize a "running" indicator light when Contactor A is active.

To truly grasp these concepts, it is best to refer to a visual representation. The following section provides a detailed example that illustrates these principles in practice.

Now, take a moment to carefully examine the detailed schematic presented in the next section. It offers a clear and practical demonstration of how to implement these wiring techniques effectively.