Understanding a Battery Management System Wiring Diagram is crucial for anyone working with battery packs, especially those in electric vehicles, renewable energy storage, or portable electronics. This diagram is the blueprint that details how all the components of a BMS are interconnected, ensuring safe, efficient, and long-lasting battery operation. A clear Battery Management System Wiring Diagram is the cornerstone of a reliable battery system.

Decoding the Battery Management System Wiring Diagram

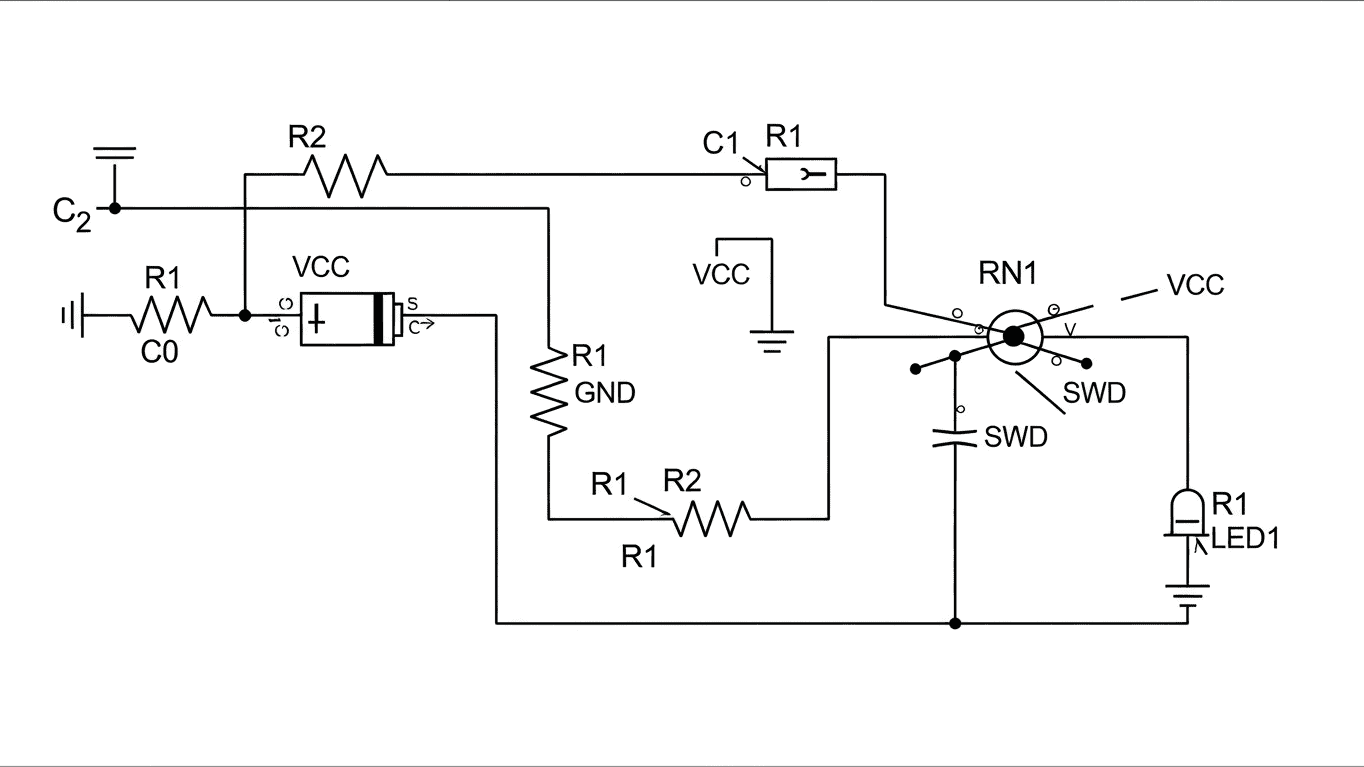

A Battery Management System Wiring Diagram isn't just a random collection of wires; it's a meticulously organized schematic that illustrates the electrical connections between the Battery Management System (BMS) controller, individual battery cells, sensors, and external interfaces. Its primary purpose is to facilitate communication and control over the entire battery pack. This involves monitoring critical parameters like voltage, current, and temperature for each cell or module. The BMS then uses this information to make intelligent decisions, such as balancing cell voltages, preventing overcharging or deep discharge, and protecting the battery from damage.

The complexity of a Battery Management System Wiring Diagram can vary significantly depending on the application. For a simple consumer device, it might be relatively straightforward. However, for a large electric vehicle battery pack, the diagram can become quite intricate. Key components typically found on such a diagram include:

- BMS Microcontroller (the brain of the system)

- Cell Voltage Sense Lines

- Temperature Sensors

- Current Sensor (often a shunt resistor or Hall effect sensor)

- Balancing Circuitry (for charge and discharge balancing)

- Communication Interfaces (e.g., CAN bus, SMBus)

- Power Supply Inputs/Outputs

- Safety Relays and Fuses

The Battery Management System Wiring Diagram serves multiple vital functions:

- System Design and Integration: It guides engineers in designing the physical layout of the BMS and integrating it with the battery pack and the overall system.

- Troubleshooting and Maintenance: When issues arise, a clear wiring diagram is invaluable for pinpointing faults and performing repairs efficiently.

- Safety Assurance: By detailing all safety-related connections, the diagram helps ensure that overcurrent, overvoltage, and thermal protection mechanisms are correctly implemented.

- Performance Optimization: Understanding the wiring allows for adjustments and configurations that can maximize battery life and performance.

The ability to correctly interpret and utilize a Battery Management System Wiring Diagram is absolutely critical for the safe and effective operation of any advanced battery system.

Let's consider a simplified example of what you might find in a basic diagram:

| Component | Connection Point | Function |

|---|---|---|

| BMS Controller | Main Power Input | Receives power to operate |

| Cell 1 Voltage Sense | BMS Input Pin A | Monitors voltage of the first cell |

| Temperature Sensor | BMS Input Pin B | Measures ambient or cell temperature |

| Current Sensor Output | BMS Input Pin C | Provides real-time current data |

For a comprehensive understanding of your specific battery system, it is essential to refer to the detailed Battery Management System Wiring Diagram provided by the manufacturer. This resource is indispensable for accurate assembly, troubleshooting, and safe operation. Consult the specific documentation for your system.