Understanding the "Absolute Encoder Wiring Diagram" is crucial for anyone integrating position feedback into their systems. This diagram serves as a roadmap, detailing how to correctly connect an absolute encoder to its host controller, ensuring accurate and reliable position data. A well-understood "Absolute Encoder Wiring Diagram" prevents costly errors and ensures optimal performance.

Understanding the Absolute Encoder Wiring Diagram

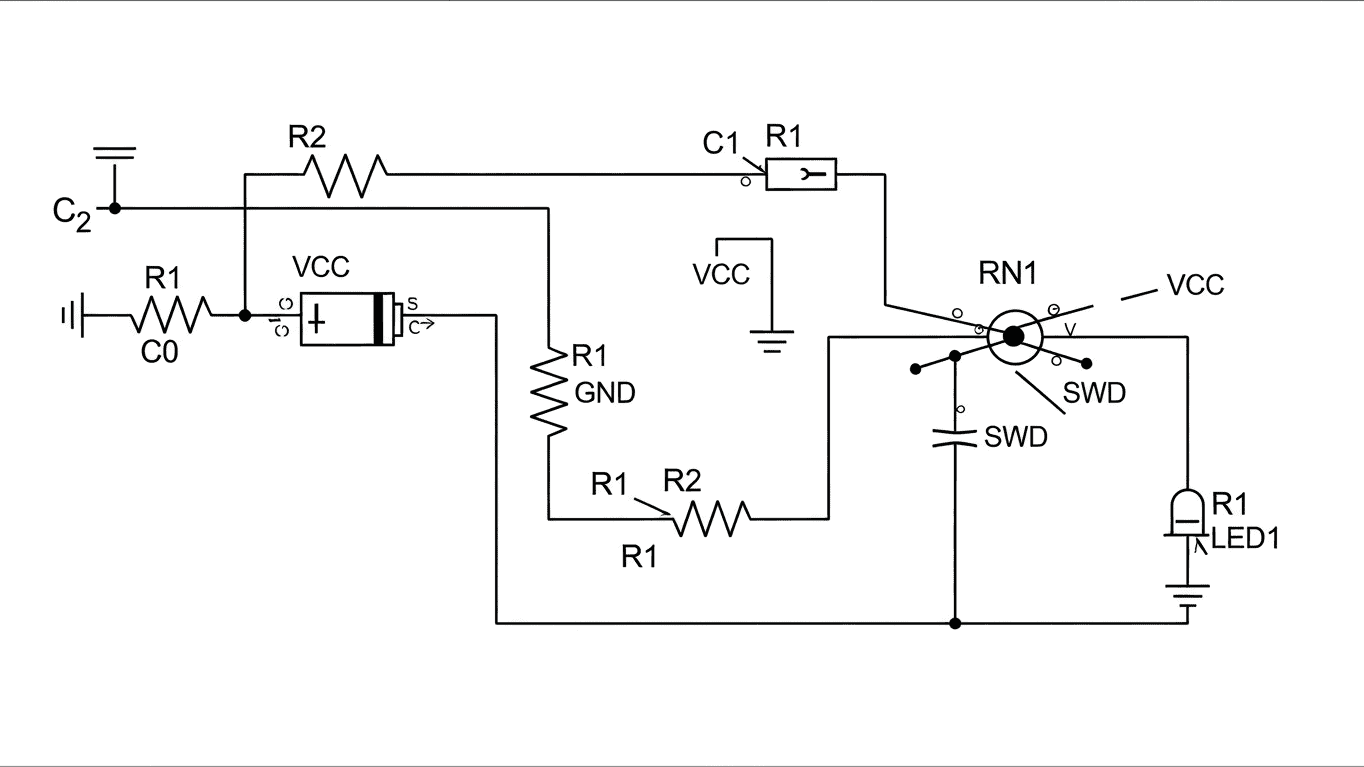

An "Absolute Encoder Wiring Diagram" outlines the electrical connections required to interface an absolute encoder with a control system. Unlike incremental encoders, absolute encoders provide a unique digital code for each distinct shaft position, meaning they know their exact position even after a power cycle. This is achieved through a complex internal structure that generates a unique binary or Gray code output. The wiring diagram dictates how these output signals, along with power and ground connections, are routed to the microcontroller, PLC, or other processing unit.

The primary purpose of an "Absolute Encoder Wiring Diagram" is to ensure that the encoder's signals are correctly interpreted by the receiving device. This involves understanding:

- Power Supply: The voltage and current requirements of the encoder.

- Data Outputs: The type of interface (e.g., SSI, BiSS, parallel, serial) and the specific pins for data transmission.

- Control Signals: Any clock, data valid, or enable signals required by the communication protocol.

- Grounding: Proper grounding is essential for signal integrity and noise reduction.

The importance of meticulously following the Absolute Encoder Wiring Diagram cannot be overstated for achieving precise and dependable positional information.

Different types of absolute encoders utilize varying wiring configurations:

- SSI (Synchronous Serial Interface) : Typically involves a clock input and a data output line. The diagram will show how these connect to the controller's serial communication pins.

- Parallel Output : These encoders output the position as a multi-bit word on several dedicated pins. The wiring diagram will show each data pin connecting to a separate input on the controller.

- Serial Interfaces (e.g., SPI, I²C) : These use more standardized serial communication protocols, and the diagram will illustrate the specific connections for clock, data in/out, and chip select.

A typical "Absolute Encoder Wiring Diagram" might look something like this:

| Encoder Pin | Controller Pin | Signal Type |

|---|---|---|

| VCC / Power | DC Power Input | Power Supply |

| GND / Ground | Ground | Ground |

| DATA | Data Input | Position Data |

| CLOCK | Clock Output | Timing Signal |

For the most accurate and detailed information specific to your chosen encoder model, refer to the "Absolute Encoder Wiring Diagram" provided by the manufacturer. This guide is an excellent starting point for understanding the general principles.