Understanding the Ac Motor Run Capacitor Wiring Diagram is crucial for anyone working with single-phase AC motors. This diagram serves as a roadmap, guiding you through the proper connections for the capacitor that helps your motor run efficiently and smoothly. Whether you're a DIY enthusiast or a professional technician, a clear grasp of the Ac Motor Run Capacitor Wiring Diagram ensures safe and effective motor operation.

The Role of the Run Capacitor in AC Motors

A run capacitor, also known as a continuous capacitor, is an essential component in many single-phase AC motors. Its primary function is to improve the motor's running performance by providing a continuous phase shift. Unlike start capacitors, which are typically disconnected once the motor reaches a certain speed, run capacitors remain connected throughout the motor's operation. This continuous connection helps to maintain a consistent rotating magnetic field within the motor, leading to smoother operation and increased torque. The correct wiring of the run capacitor, as detailed in an Ac Motor Run Capacitor Wiring Diagram, is paramount for preventing motor damage and ensuring optimal efficiency.

In single-phase AC motors, the power supply provides a single alternating current. However, to generate the rotating magnetic field necessary for the motor to turn, two phased currents are needed. The run capacitor, in conjunction with the motor's winding, creates this necessary phase difference. This is often achieved by connecting the capacitor in series with an auxiliary winding (often called the "start winding" or "run winding," depending on the motor's specific design). The capacitor's impedance causes the current in this auxiliary winding to lag behind the current in the main winding, thereby creating the rotating magnetic field.

Here's a breakdown of how the run capacitor contributes:

- Phase Shift: It creates a phase difference between the currents in the main and auxiliary windings.

- Torque Improvement: This phase shift enhances the motor's starting and running torque.

- Efficiency: By ensuring a more consistent magnetic field, it reduces energy waste and improves overall efficiency.

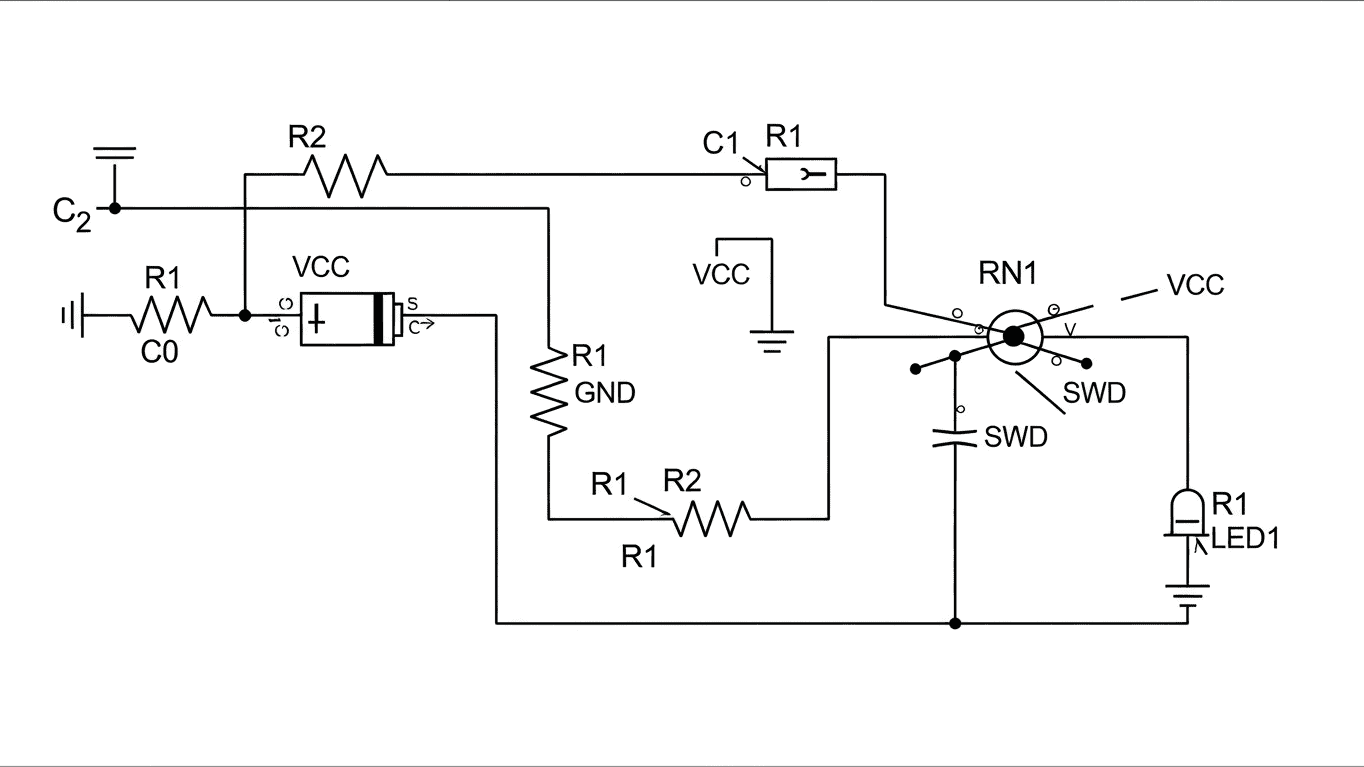

A typical Ac Motor Run Capacitor Wiring Diagram will illustrate these connections. For example, it will show:

- The connection of one terminal of the run capacitor to one side of the main winding.

- The connection of the other terminal of the run capacitor to one side of the auxiliary winding.

- The common connection point for the other ends of both the main and auxiliary windings, which then connects to the power supply.

A simplified representation can be seen in this conceptual table:

| Component | Connection Point |

|---|---|

| Run Capacitor (Terminal 1) | Main Winding (One End) |

| Run Capacitor (Terminal 2) | Auxiliary Winding (One End) |

| Main Winding (Other End) & Auxiliary Winding (Other End) | Common Point (Connects to Power Supply) |

Reviewing the specific Ac Motor Run Capacitor Wiring Diagram for your motor model is essential. Always consult the manufacturer's documentation for the most accurate and safe wiring instructions. This will ensure you connect the capacitor correctly, preventing potential damage to the motor or electrical hazards.

To ensure you're making the correct connections and understanding the nuances of your specific motor, please refer to the Ac Motor Run Capacitor Wiring Diagram provided by the manufacturer. This detailed diagram is your definitive guide.