Understanding the Allen Bradley Safety Relay Wiring Diagram is crucial for anyone involved in industrial automation and machine safety. These diagrams are the blueprints that ensure your safety systems function correctly and reliably, protecting personnel and equipment. A properly interpreted Allen Bradley Safety Relay Wiring Diagram is your roadmap to safe and efficient operation.

The Core of Machine Safety: Understanding Allen Bradley Safety Relays

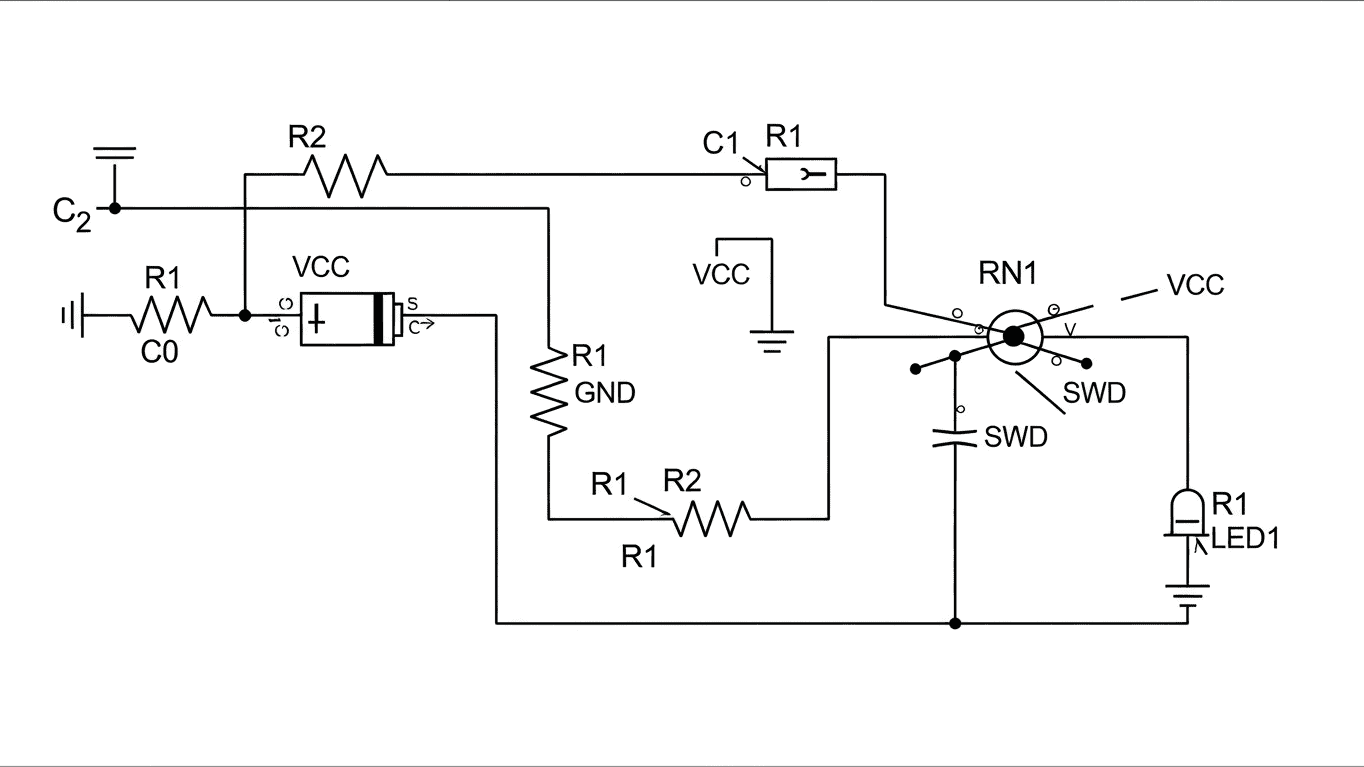

An Allen Bradley Safety Relay Wiring Diagram isn't just a collection of lines and symbols; it's a meticulously designed schematic that illustrates the interconnectedness of safety devices and the logic of their operation. These relays are designed to monitor safety inputs, such as emergency stop buttons, light curtains, and safety mats, and to de-energize hazardous machinery in a controlled and predictable manner. The integrity of your safety system hinges on the accurate interpretation and implementation of the Allen Bradley Safety Relay Wiring Diagram.

The primary function of an Allen Bradley safety relay is to provide redundant and diverse circuitry to prevent single-point failures from leading to hazardous situations. When a safety device is activated, the relay processes this input through its internal logic and, if the safety conditions are met, it opens its output contacts, cutting power to the hazardous motion of the machine. Different types of safety relays exist, each with specific applications:

- Single Function Relays: Designed for one specific safety task (e.g., E-stop monitoring).

- Dual Function Relays: Can monitor two different safety inputs simultaneously.

- Monitoring Relays: Used for more complex safety functions and logic.

The wiring of these relays is critical. A typical Allen Bradley Safety Relay Wiring Diagram will show connections for:

| Component | Connection Type | Purpose |

|---|---|---|

| Safety Input Devices | Normally Closed (NC) or Normally Open (NO) contacts | Detecting hazardous conditions |

| Safety Relay Control Power | AC or DC voltage | Energizing the relay's internal logic |

| Safety Relay Output Contacts | N.O. or N.C. contacts (redundant) | Controlling the power to the machine's hazardous motion |

| Reset Function | Manual or automatic | Restarting the machine after a safety fault is cleared |

Following the Allen Bradley Safety Relay Wiring Diagram precisely ensures that the safety circuit's redundancy and diagnostic capabilities are maintained. This includes proper wiring of reset circuits, which are often manual to prevent unintended machine restarts.

For detailed schematics and specific model instructions, refer to the comprehensive documentation and resources provided by Allen Bradley. These official resources are the definitive source for all Allen Bradley Safety Relay Wiring Diagram requirements.